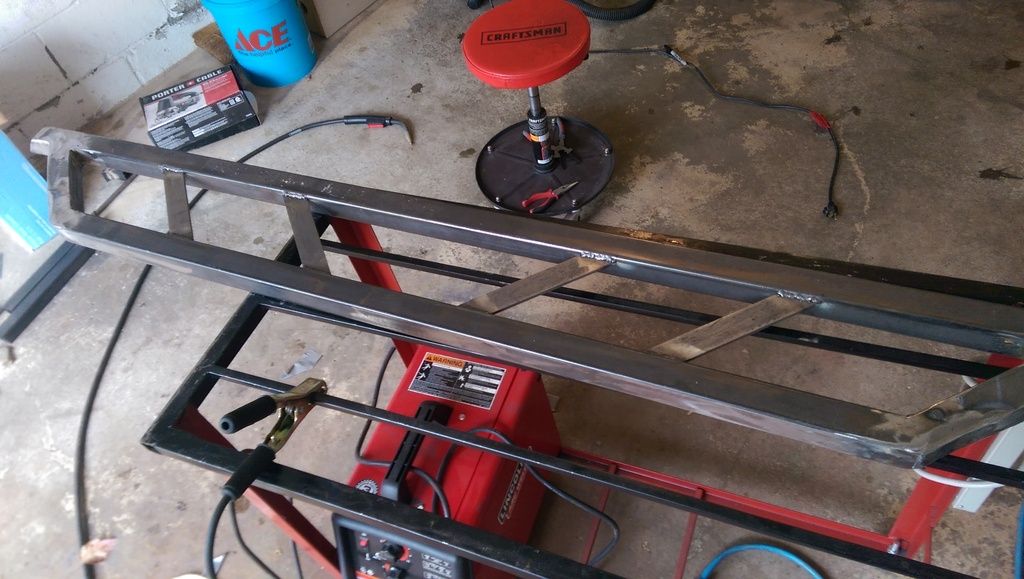

First, I went with all square 1 1/2 hot rolled steel tubing for the structure. To be honest, I can't remember the gage, but I think it's something like 1/8 inch. Not super beefy, but it should provide pretty decent protection without adding too much weight to my daily driver. I can't wait until some ass hat opens their door into my truck and dings their door on the sliders. Anyway, here are pictures:

First, I cut and assembled to pieces to see how they laid out together

Then, I welded everything up. The hardest part was probably capping the ends. In the second picture, you'll see extra welds because I had the angle at the end wrong like an idiot. It's supposed to contour the body shape, so I had to cut it off, turn it the right way, and weld it back on.

Then, repeat for the other side

Next, I welded in some cross braces.

Finally, I ground all the welds down for a smoother finish that will look better and hopefully deter rust that would otherwise gather in the weld seams. That part sucked too because sometimes I would find occlusions in my welds or would grind too far and have to go back and fill spots in with more welding. Not fun or good for the base metal.

But, it's pretty now.

Next up is mounting to the frame. I'm fabricating u shaped brackets that will bolt around the frame because I don't want to compromise structural integrity by welding or drilling the frame.